This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Controls System and Remote Monitoring Support

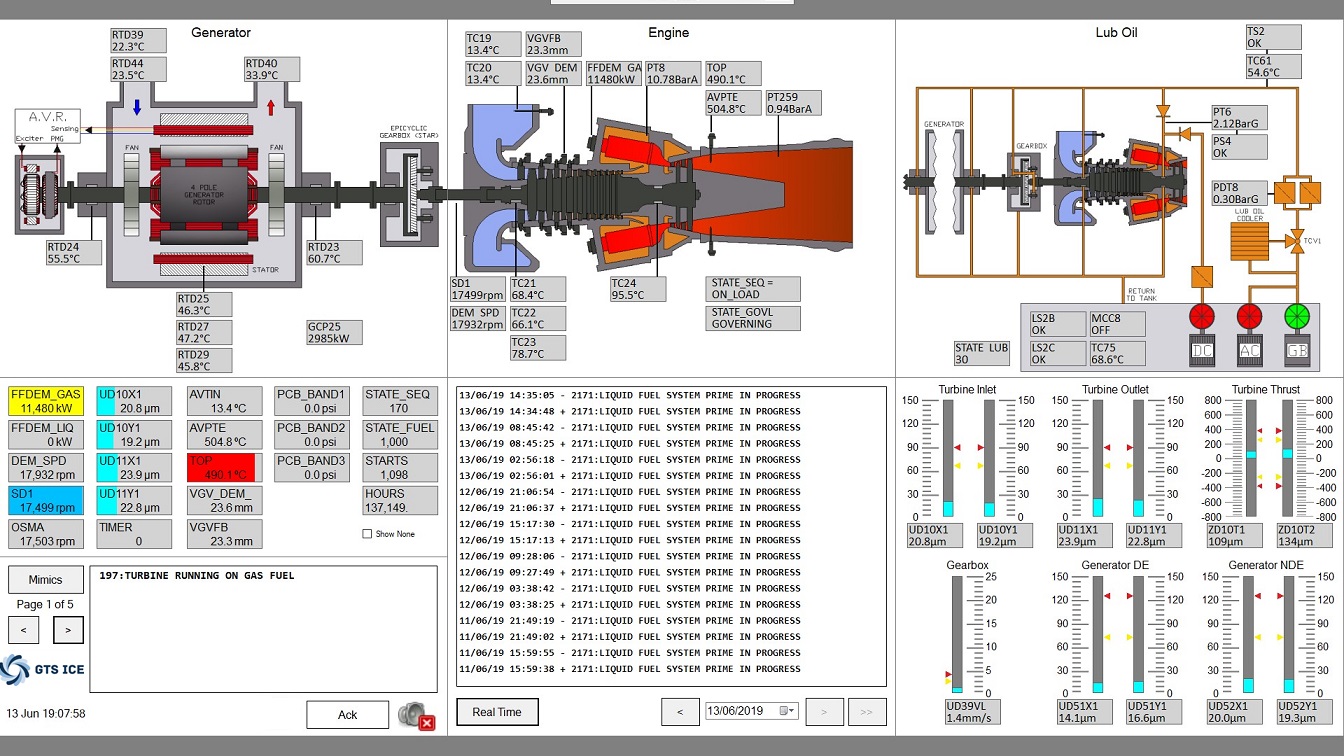

Gas Turbine Services appreciates that upgrading your existing Rustronic MKII Controls System is not always economically viable or required and therefore has developed capabilities to offer support for this system through the remainder of your plant’s lifetime. GTS can offer life extension of your Rustronic MKII controls system by providing If the operator requires complete Controls Systems Upgrades and Retrofits, GTS ICE controls solutions are designed specifically for the Upgrade and Retrofit of SGT / Ruston Gas Turbine controls and are easily adapted to site specific requirements. KEY FEATURES: